Belt Cleaning system

Is your conveyor belt sanitation process taking too much time, using too much water & energy, and disrupting your production schedule?

HALT, a sister company of Safari Belting, is proud to introduce a novel, conveyor belt cleaning system, which will improve belt sanitation and reduce the time and resources needed to do the job.

What makes the HALT Belt Cleaning System different from other clean-in-place systems??

- Programable for automated, individual applications of low-pressure presoak, foam, sanitizer, and high-pressure rinse.

- Sequential, “hands-free” completion of timed applications reduces water consumption, labor & energy costs, and sanitation belt damage.

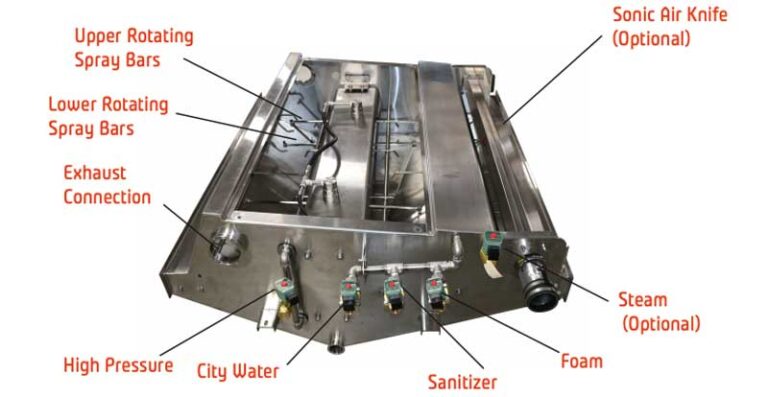

- High-pressure, stainless steel rotating spray bars with nozzles simultaneously clean the full width of both the top and bottom of the conveyor belt.

- Steam and air-knife options available for additional customization.

- 304 stainless steel, fully assembled, compact design is installed in the belt return area of the conveyor.

- Cleans all types of conveyor belting up to 60” wide.

- Access lid for easy cleaning and inspection.

- 1.5” (38 mm) tri-clamp, on sumped floor, for connection to waste-water removal.

- Complete AB PLC control assembly.

- UL508A listed.

- Nema 4x/IP66 enclosure for controls.

- Available for single or dual belt cleaning systems.

Safari HALT Automatic belt Cleaning System

Optional Features

Steam Bar Assembly

- Adds Steam Application To Wash Operations

- Designed For Low Pressure Steam 15 psi/1 Bar

*Steam Supply Provided By Customer (End User).

Sonic HV Blower Assembly

- High Velocity Blower And Air Knife Assembly For Removal Of Wash Water Immediately After Belt Washing Operations.

- Silencer/filter Assembly

- Stainless Steel Air Knives With 3” Butterfly Valve, Sleeves And Clamps.

- Wash-down Rated Motor Assembly Available.

- Blower And HP Will Be Sized To Provide Adequate Air Flow To The Water Removal Air Knife Assembly

*Customer (End User) Responsible For All Electrical & Plumbing Requirements.

Pressure Washer Assembly

- Industrial Rated Pressure Washer For Supplying Water To The Washer Assembly At Approx. 1,200 psi/82 Bar.

- GPM Rate To Be Sized to Supply the Necessary Water Volume Required.

- Junction Box Locally Mounted For Customer Connections And Housing Of The Motor Protector And Contractor

*Customer (End User) Responsible For Interconnection Wiring And Plumbing

Control Assembly

- Complete AB PLC Control Assembly For Automated Control Of The Washer Assembly.

- UL508A Listed.

- Nema 4x/IP66 Enclosure For Controls

- Available For Single Or Dual Belt Washer Systems.